#feedforward control systems…

Explore tagged Tumblr posts

Text

anyway i think the most fun class i’ve ever taken is chemical systems control and it really made me feel smart so there’s that

#sybau challenge (100% fail) .ᐟ#feedback control systems…#feedforward control systems…#im foaming at the mouth

1 note

·

View note

Note

How much/quickly do you think AI is going to expand and improve materials science? It feels like a scientific field which is already benefiting tremendously.

My initial instinct was yes, MSE is already benefiting tremendously as you said. At least in terms of the fundamental science and research, AI is huge in materials science. So how quickly? I'd say it's already doing so, and it's only going to move quicker from here. But I'm coming at this from the perspective of a metallurgist who works in/around academia at the moment, with the bias that probably more than half of my research group does computational work. So let's take a step back.

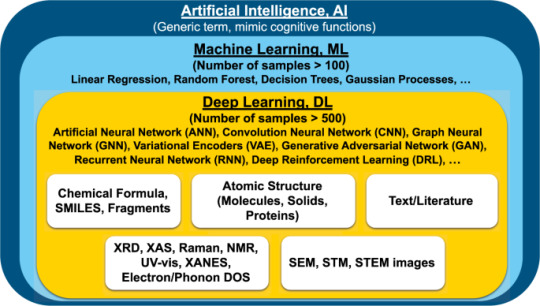

So, first, AI. It's... not a great term. So here's what I, specifically, am referring to when I talk about AI in materials science:

Most of the people I know in AI would refer to what they do as machine learning or deep learning, so machine learning tends to be what I use as a preferred term. And as you can see from the above image, it can do a lot. The thing is, on a fundamental level, materials science is all about how our 118 elements (~90, if you want to ignore everything past uranium and a few others that aren't practical to use) interact. That's a lot of combinations. (Yes, yes, we're not getting into the distinction between materials science, chemistry, and physics right now.) If you're trying to make a new alloy that has X properties and Y price, computers are so much better at running through all the options than a human would be. Or if you have 100 images you want to analyze to get grain size—we're getting to the point where computers can do it faster. (The question is, can they do it better? And this question can get complicated fast. What is better? What is the size of the grain? We're not going to get into 'ground truth' debates here though.) Plenty of other examples exist.

Even beyond the science of it all, machine learning can help collect knowledge in one place. That's what the text/literature bubble above means: there are so many old articles that don't have data attached to them, and I know people personally who are working on the problem of training systems to pull data from pdfs (mainly tables and graphs) so that that information can be collated.

I won't ramble too long about the usage of machine learning in MSE because that could get long quickly, and the two sources I'm linking here cover that far better than I could. But I'll give you this plot from research in 2019 (so already 6 years out of date!) about the growth of machine learning in materials science:

I will leave everyone with the caveat though, that when I say machine learning is huge in MSE, I am, as I said in the beginning, referring to fundamental research in the field. From my perspective, in terms of commercial applications we've still got a ways to go before we trust computers to churn out parts for us. Machine learning can tell researchers the five best element combinations to make a new high entropy alloy—but no company is going to commit to making that product until the predictions of the computer (properties, best processing routes, etc.) have been physically demonstrated with actual parts and tested in traditional ways.

Certain computational materials science techniques, like finite element analysis (which is not AI, though might incorporate it in the future) are trusted by industry, but machine learning techniques are not there yet, and still have a ways to go, as far as I'm aware.

So as for how much? Fundamental research for now only. New materials and high-throughput materials testing/characterization. But I do think, at some point, maybe ten years, maybe twenty years down the line, we'll start to see parts made whose processing was entirely informed by machine learning, possibly with feedback and feedforward control so that the finished parts don't need to be tested to know how they'll perform (see: Digital twins (Wikipedia) (Phys.org) (2022 article)). At that point, it's not a matter of whether the technology will be ready for it, it'll be a matter of how much we want to trust the technology. I don't think we'll do away with physical testing anytime soon.

But hey, that's just one perspective. If anyone's got any thoughts about AI in materials science, please, share them!

Source of image 1, 2022 article.

Source of image 2, 2019 article.

#Materials Science#Science#Artificial Intelligence#Replies#Computational materials science#Machine learning

22 notes

·

View notes

Text

Interesting Papers for Week 10, 2025

Simplified internal models in human control of complex objects. Bazzi, S., Stansfield, S., Hogan, N., & Sternad, D. (2024). PLOS Computational Biology, 20(11), e1012599.

Co-contraction embodies uncertainty: An optimal feedforward strategy for robust motor control. Berret, B., Verdel, D., Burdet, E., & Jean, F. (2024). PLOS Computational Biology, 20(11), e1012598.

Distributed representations of behaviour-derived object dimensions in the human visual system. Contier, O., Baker, C. I., & Hebart, M. N. (2024). Nature Human Behaviour, 8(11), 2179–2193.

Thalamic spindles and Up states coordinate cortical and hippocampal co-ripples in humans. Dickey, C. W., Verzhbinsky, I. A., Kajfez, S., Rosen, B. Q., Gonzalez, C. E., Chauvel, P. Y., Cash, S. S., Pati, S., & Halgren, E. (2024). PLOS Biology, 22(11), e3002855.

Preconfigured cortico-thalamic neural dynamics constrain movement-associated thalamic activity. González-Pereyra, P., Sánchez-Lobato, O., Martínez-Montalvo, M. G., Ortega-Romero, D. I., Pérez-Díaz, C. I., Merchant, H., Tellez, L. A., & Rueda-Orozco, P. E. (2024). Nature Communications, 15, 10185.

A tradeoff between efficiency and robustness in the hippocampal-neocortical memory network during human and rodent sleep. Hahn, M. A., Lendner, J. D., Anwander, M., Slama, K. S. J., Knight, R. T., Lin, J. J., & Helfrich, R. F. (2024). Progress in Neurobiology, 242, 102672.

NREM sleep improves behavioral performance by desynchronizing cortical circuits. Kharas, N., Chelaru, M. I., Eagleman, S., Parajuli, A., & Dragoi, V. (2024). Science, 386(6724), 892–897.

Human hippocampus and dorsomedial prefrontal cortex infer and update latent causes during social interaction. Mahmoodi, A., Luo, S., Harbison, C., Piray, P., & Rushworth, M. F. S. (2024). Neuron, 112(22), 3796-3809.e9.

Can compression take place in working memory without a central contribution of long-term memory? Mathy, F., Friedman, O., & Gauvrit, N. (2024). Memory & Cognition, 52(8), 1726–1736.

Offline hippocampal reactivation during dentate spikes supports flexible memory. McHugh, S. B., Lopes-dos-Santos, V., Castelli, M., Gava, G. P., Thompson, S. E., Tam, S. K. E., Hartwich, K., Perry, B., Toth, R., Denison, T., Sharott, A., & Dupret, D. (2024). Neuron, 112(22), 3768-3781.e8.

Reward Bases: A simple mechanism for adaptive acquisition of multiple reward types. Millidge, B., Song, Y., Lak, A., Walton, M. E., & Bogacz, R. (2024). PLOS Computational Biology, 20(11), e1012580.

Hidden state inference requires abstract contextual representations in the ventral hippocampus. Mishchanchuk, K., Gregoriou, G., Qü, A., Kastler, A., Huys, Q. J. M., Wilbrecht, L., & MacAskill, A. F. (2024). Science, 386(6724), 926–932.

Dopamine builds and reveals reward-associated latent behavioral attractors. Naudé, J., Sarazin, M. X. B., Mondoloni, S., Hannesse, B., Vicq, E., Amegandjin, F., Mourot, A., Faure, P., & Delord, B. (2024). Nature Communications, 15, 9825.

Compensation to visual impairments and behavioral plasticity in navigating ants. Schwarz, S., Clement, L., Haalck, L., Risse, B., & Wystrach, A. (2024). Proceedings of the National Academy of Sciences, 121(48), e2410908121.

Replay shapes abstract cognitive maps for efficient social navigation. Son, J.-Y., Vives, M.-L., Bhandari, A., & FeldmanHall, O. (2024). Nature Human Behaviour, 8(11), 2156–2167.

Rapid modulation of striatal cholinergic interneurons and dopamine release by satellite astrocytes. Stedehouder, J., Roberts, B. M., Raina, S., Bossi, S., Liu, A. K. L., Doig, N. M., McGerty, K., Magill, P. J., Parkkinen, L., & Cragg, S. J. (2024). Nature Communications, 15, 10017.

A hierarchical active inference model of spatial alternation tasks and the hippocampal-prefrontal circuit. Van de Maele, T., Dhoedt, B., Verbelen, T., & Pezzulo, G. (2024). Nature Communications, 15, 9892.

Cognitive reserve against Alzheimer’s pathology is linked to brain activity during memory formation. Vockert, N., Machts, J., Kleineidam, L., Nemali, A., Incesoy, E. I., Bernal, J., Schütze, H., Yakupov, R., Peters, O., Gref, D., Schneider, L. S., Preis, L., Priller, J., Spruth, E. J., Altenstein, S., Schneider, A., Fliessbach, K., Wiltfang, J., Rostamzadeh, A., … Ziegler, G. (2024). Nature Communications, 15, 9815.

The human posterior parietal cortices orthogonalize the representation of different streams of information concurrently coded in visual working memory. Xu, Y. (2024). PLOS Biology, 22(11), e3002915.

Challenging the Bayesian confidence hypothesis in perceptual decision-making. Xue, K., Shekhar, M., & Rahnev, D. (2024). Proceedings of the National Academy of Sciences, 121(48), e2410487121.

#neuroscience#science#research#brain science#scientific publications#cognitive science#neurobiology#cognition#psychophysics#neurons#neural computation#neural networks#computational neuroscience

15 notes

·

View notes

Text

Xanadu Achieves Scalable Gottesman–Kitaev–Preskill States

States Gottesman–Kitaev–Preskill

Xanadu leads photonic quantum computing with their development of a scalable building block for fault-tolerant quantum computers. The achievement involves on-chip Gottesman–Kitaev–Preskill state production and was initially reported in January 2025 by Nature and summarised in June 2025. “First-of-its-kind achievement” and “key step towards scalable fault-tolerant quantum computing” describe this work.

Understanding GKP States' Importance

GKP states are error-tolerant photonic qubits. These complex quantum states consist of photons stacked in specific ways. Due to its unique structure, quantum error correcting methods may identify and fix phase shifts and photon loss. Zachary Vernon, CTO of Xanadu, calls GKP states “the optimal photonic qubit” because they enable quantum logic operations and error correction “at room temperature and using relatively straightforward, deterministic operations.” It has always been challenging to construct high-quality Gottesman–Kitaev–Preskill States on an integrated platform. This discovery advances continuous-variable quantum computing architectures by overcoming that obstacle.

GKP states provide fault-tolerant computing by using linear optics and measurement algorithms, unlike probabilistic entanglement methods that require repeated trials and complex feed-forward control. They fit well with hybrid systems because they generate quantum networks that link chips or modules or create larger cluster states for measurement-based computation.

Quantum systems' interoperability with optical fibre makes scaling easy, allowing them to be distributed among system components or data centres. This demonstration changed photonic quantum computing by taking a different approach from superconducting and trapped-ion platforms and bringing these systems closer to utility-scale quantum machine error thresholds.

Aurora: Photonic Quantum Computing Architectur

The “sub-performant scale model of a quantum computer” “Aurora” represents Xanadu's work. This system uses scalable, rack-deployed modules connected by fibre optics to incorporate all basic components. With 35 photonic devices, 84 squeezers, and 36 photon-number-resolving (PNR) detectors, Aurora provides 12 physical qubit modes each clock cycle. All system components except the cryogenic PNR detection array are operated by a single server computer and fit into four server racks.

Aurora's key technologies and their functions:

Silicon nitride waveguides feature minimal optical losses. This waveguide uses 300 mm wafers, which are common in semiconductor production. Newer chips based on Ligentec SA's 200-mm silicon-nitride waveguide architecture show potential for better squeezing and lower chip-fiber coupling losses.

The efficiency of photon-number-resolving (PNR) detectors is above 99%. In 12-mK dilution coolers, 36 transition edge sensor (TES) arrays form its base. These TES detectors cycle at 1 MHz and detect up to seven photon counts with little miscategorization error. Despite being highly effective, PNR detection efficiencies of over 99% are needed to meet the architecture's strict P1 path loss constraints.

Loss-optimized optical packaging—including accurate alignment, chip mounting, and fibre connections—was emphasised. This protects critical quantum information during routing and measurement.

The refinery array has six photonic integrated circuits (PICs) on a thin-film lithium-niobate substrate. Each refinery's two binary trees of electro-optic Mach-Zehnder modulator switches dynamically select the best output state based on PNR detection system feedforward instructions. Even though current Aurora refinery chips use probability-boosting multiplexing and Bell pair synthesis, future generations will use homodyne detectors to complete the adaptive breeding method.

Interconnects: Phase- and polarization-stabilized fiber-optical delay lines connect the refinery to QPU and refinery modules. These delays allow temporal entanglement and buffer information heralding in the cluster state.

Experiments and Results

Two large trials benchmarked Aurora's main features.

To generate a 12 × N-mode Gaussian cluster state, the system was set to send squeezed states to the QPU array. Data was collected at 1 MHz for two hours to synthesise and measure a macronode cluster state with 86.4 billion modes. Despite substantial optical losses (approximately 14 dB), the nullifier variances remained below the vacuum noise threshold, proving squeezing and cluster state entanglement.

Detecting Repetition Code Errors: This experiment showed the system's feedforward and non-Gaussian-state synthesis using low-quality GKP states. In real time, the QPU decoder assessed the system's two (foliated) repetition code checks. The decoder calculated bit values and phase error probabilities to change the measurement basis for the next time step.

Limitations and Prospects

Despite these notable examples, the “component performance gap” between existing capabilities and fault tolerance needs remains large. The main limiter of quantum state purity and coherence is optical loss. Ideal designs for fault-tolerant operation require loss budgets of about 1%, whereas the Aurora system lost 56% for heralding pathways (P1) and nearly 95% for heralded optical paths (P1 and P2).

Xanadu's future projects include:

Hardware improvements: Chip fabrication, waveguide geometry, and packaging are optimised to improve fidelity and reduce optical loss. The photonic components' insertion loss must be improved by 20-30 times (on a decibel scale).

Architectural Refinements: Testing cutting-edge hardware-level photon generation and detection rates and error mitigation measures to reduce loss and imperfection.

Integration and Scaling: combining the new GKP generation methods with Aurora's networking, error correcting protocols, and logic gates. The company believes scalable, semiconductor-compatible platforms can mass-produce, modify, and monitor error-correcting components for modular quantum computing.

Even though quantum hardware across all platforms is currently in the noisy intermediate-scale quantum (NISQ) period, Xanadu's work shows how to scale photonic quantum computers to address real applications. Fiber-optical networking, classical control electronics, and photonic-chip fabrication can scale and modularise a realistic photonic architecture. We must continuously improve optical GKP-based architectures to find the most hardware-efficient and imperfection-tolerant systems.

#GottesmanKitaevPreskillState#GKPstates#physicalqubit#QuantumProcessingUnit#Xanadu#quantumcomputing#News#Technews#Technology#Technologynews#Technologytrends#Govindhtech

0 notes

Text

Achieving Consistent Pressure Control: Mechanisms in Gas and Steam Pressure Reducing Stations

Effectively managing the consistency of pressure levels across gas and steam systems during operations in industrial settings ensures efficiency and the highest safety levels of equipment integrity over the long term.

Large systems often house pressure-reducing stations (PRS), which reduce high-pressure gases or steam to a level suitable for end users or other equipment. Complex control mechanisms must equip PRS to maintain the operating pressure level, regardless of flow, temperature, or external conditions.

A multitude of technologies, from pressure sensors to the smartest control algorithms, apply to the subject of holding pressure constant. This blog elaborates on the processes of gas and steam pressure-reducing and desuperheating stations, including different components and technologies that support precise control of pressure.

Pressure Reducing Stations: The Bottom Line

As the name implies, pressure-reducing stations play an important function as far as the critical infrastructure is involved. This type of station primarily drives gases or steam away from their high-pressure source to a more manageable one.

Pressure-reducing stations have a wide range of applications, from natural gas transmission networks to steam distribution in industrial plants, as their titles suggest. For instance, a natural gas system can transport gas from a gas gathering system at pressures exceeding 1000 psi (pounds per square inch).

However, it is too high for efficient and safe usage in homes and industries. Pressure-reducing stations lower the pressure to a much lower, discrete level of around 50–60 psi for distribution to buyers of residential and commercial property.

Types of Control of Pressure Mechanisms

Every PR station has a variety of control system types, each with its unique composition and functionality. Of all possible types of control mechanisms, the most commonly used ones are the specific types listed below:

Regulator Valves: Regulator valves, which operate by adjusting the valve opening in response to pressure changes at the flowing medium, are the simplest pressure control mechanism in pipeline systems for any kind of gas or steam detection rate adjustment.

Control Valves are an integral part of a sophisticated control system, responding to external control signals to regulate pressure. Conditions such as these features cause the valve's position to momentarily change and its flow capacity to alter, ensuring uniform pressure within a specific range.

Bypass Valves: In certain systems, bypass valves are positioned when necessary to redirect excess flow around the pressure reduction valve. The flow ensures that the pressure stays within the desired range due to its inherent properties, protecting against fluctuations in the upstream flow or pressure.

Use of pressure sensors and transducers.

Pressure sensors and transducers play a crucial role in accurately managing pressure across all operational process regions at the reducing station. These sensors continuously monitor the pressure, sending the obtained data to the control system for real-time evaluation and subsequent appropriate responses.

What Are Pressure Sensors? Pressure sensors convert physical pressures to electric signals to provide continuous feedback about pressure inside a system. This is essential for better regulation and control of the system.

What Are Pressure Transducers? Pressure transducers can convert pressure to an analog or digital signal, much like a sensor. We use these devices to measure pressure more precisely, which we can then practically apply within another control system for more sophisticated regulation.

PID Control Systems

Ideal process control Pressure regulation using a feedback process ranges from base control and feedforward to proportional, integral, and derivative control for many processes. PID control is the most advanced of these well-known base regulatory strategies.

It conjures up many possibilities beyond simply controlling static and steady-state process responses. The "PID" controller earned its name due to its ability to dynamically adjust each of the three variables that collectively produce the control signal in response to errors.

Proportional Control (P) is the act of controlling in proportion to the difference between the actual and the desired pressure.

Flow and pressure relationships

In pressure-reducing stations, it is essential to understand the relationship of flow with pressure and how the system works. When the system loses energy to make gas or steam flow, the pressure typically decreases. Conversely, as the flow decreases, the pressure will increase. The control system must manage this relationship, as a change in flow will result in significant pressure changes.

In order to manage the various changes, pressure control mechanisms must dynamically adjust themselves according to changing flow. For instance, when demand suddenly increases, a control valve may open more to accommodate larger flows, while simultaneously adjusting the flow to maintain the required pressure level.

Dynamic Response and Pressure Stability

If requirements necessitate a dynamic response in such transient events, pressure regulator systems will first construct a well-designed station to accommodate these transient scenarios, leading to a sudden change in performance. As an example, malfunctions in valves or any changes in loads introduce sudden changes in performance.

A competent PRS will manage these transients without disturbing the requirement that pressure is steady throughout its operation, but they should not blow any large swings of pressure into the system.

Pressure Reduction Stages in Multi-Stage Systems:

In large installations, especially those where initial high pressure exists, pressure may be brought down two or more stages in these systems as a multi-stage pressure reduction station is built to reduce pressure gradually instead of one large drop; pressure drop is thus smooth and avoids undue stress impacting equipment, plus sudden pressure shocks, which could cause blowouts or otherwise make the entire network demoralizing.

Control algorithms for loading and demand variations.

These load fluctuations are very common in gas distribution and steam systems and occur frequently due to static changes in delivery quantities or pump flow rate. Control algorithms have to be capable of changing their modes of operation according to these changing processes for the pressure control system to function effectively.

The more advanced control strategies, such as predictive algorithms, foresee the future set point load changes based on historical data, meaning that the system readjusts itself to adapt before a collision of problems occurs.

Influence of Temperature on Pressure Controlling

Temperature influence can directly influence the pressure control of both gas and steam systems. This is because as temperature increases, the gas equally expands and may raise the pressure in case it is out of range. Steam systems similarly increase their pressure as the temperature increases.

To control against disturbance due to changing temperatures, pressure-reducing stations are fitted with temperature sensors that operate in conjunction with pressure sensors; these sensors help the control system to adjust the pressure up or down to compensate for the temperature changes, enabling stable control despite environmental changes.

Emergency Measures for Pressure Control

Pressure reduction stations should have a high priority in terms of overall safety. Pressure excess could lead to system failures or even calamitous accidents. Therefore, these systems are equipped with a specific type of safety mechanism:

Safety Relief Valves: These valves automatically open when the pressure surpasses a specific threshold, allowing the excess pressure to escape and preventing system damage.

Lockout mechanism: These systems feature a lockout mechanism that disables the pressure-reducing valves in the event of a malfunction or unsafe conditions, thereby prohibiting the system from operating under dangerous conditions.

The significance behind system calibration and maintenance

Regulatory recalibration and routine maintenance are crucial for achieving highly secure pressure control measures. Over time, various components, including sensors, valves, and the control systems, may wear and corrode, leading to failure in pressure control.

Monitoring and routine calibration activities are a prerequisite in maintaining system performance and warding off possible issues such as pressure swings, equipment failure, or safety hazards.

Conclusion

Operation is critical in these systems, as gas and steam pressure stations are essential elements of industrial systems that control consistent pressure and achieve high operation smoothness.

These pressure-reducing and desuperheating stations use various controls, innovative sensors, and precise control algorithms to ensure that the gas pressure remains pure and does not exceed the administrators' setpoints. They also ensure that control is not affected when flow, temperature, or demand varies.

Without complexity in the relationships between pressure, flow, temperature, and control systems, successful optimization of system performance can reduce risk and costs, while also extending the life span of equipment.

0 notes

Text

How Feedback and Feedforward Control Enhance Operational Efficiency

In the dynamic world of business, operational efficiency is essential for staying competitive. Companies must continuously improve their processes to reduce costs, streamline workflows, and enhance productivity. One powerful strategy to achieve this is by utilizing feedback and feedforward control systems. These two control mechanisms provide a framework to monitor, assess, and optimize operations effectively, ensuring that businesses can adapt to changes and improve their overall performance.

In this blog, we’ll explore how feedback and feedforward control can enhance operational efficiency and why they are crucial for modern organizations.

What is Feedback Control?

Feedback control is a reactive process where a system’s output is monitored, and adjustments are made based on the actual performance. In a business context, feedback is used to identify problems or deviations from desired outcomes after they occur, allowing companies to make corrections.

For example, in a production environment, feedback control could involve monitoring product quality and making adjustments if defects are detected. The goal is to maintain consistency and quality while addressing issues in real-time.

What is Feedforward Control?

Feedforward control, on the other hand, is a proactive approach. Instead of reacting to outcomes, feedforward control anticipates potential issues and takes steps to prevent them before they occur. By analyzing data and forecasting potential problems, feedforward control helps businesses take corrective action in advance, reducing the likelihood of disruptions and inefficiencies.

For instance, in inventory management, feedforward control could involve predicting demand based on historical data and market trends. This allows businesses to adjust their inventory levels proactively, preventing stockouts or overstocking.

How Feedback and Feedforward Control Enhance Operational Efficiency

1. Continuous Improvement and Adaptation

One of the key ways feedback and feedforward control enhance operational efficiency is through continuous improvement. Feedback loops help organizations learn from past performance. By constantly analyzing output and making adjustments, businesses can fine-tune their operations over time.

Feedforward control allows businesses to anticipate changes in the environment and adapt proactively. For example, feedforward control systems can predict changes in customer behavior or market conditions and adjust production schedules or supply chain logistics accordingly. This proactive approach minimizes downtime and ensures that the business is always aligned with external changes, helping maintain efficiency.

2. Reduced Downtime and Delays

Feedback control helps identify inefficiencies and deviations from optimal performance quickly, allowing businesses to make rapid adjustments. In manufacturing, for instance, if equipment malfunctions or production slows, feedback control allows teams to address the issue promptly, reducing downtime and minimizing production delays.

Feedforward control further reduces downtime by forecasting potential disruptions and taking preemptive actions. For example, feedforward systems might anticipate raw material shortages and order supplies ahead of time, preventing delays in production and ensuring smooth operations.

3. Better Resource Allocation

Efficient resource allocation is critical for operational efficiency. Feedback control helps businesses monitor resource usage and adjust as necessary. If energy consumption or labor costs exceed planned budgets, feedback systems can alert managers to make adjustments.

Feedforward control takes resource allocation a step further by predicting future resource needs. For example, by analyzing historical data, businesses can anticipate seasonal increases in demand for certain products, allowing them to adjust staffing levels, raw material orders, and production schedules in advance. This ensures that resources are allocated efficiently, avoiding both excess and shortage.

4. Improved Decision-Making

Both feedback and feedforward control systems provide valuable insights that can improve decision-making. Feedback allows businesses to learn from their experiences and refine their processes accordingly. Feedforward, on the other hand, uses data-driven predictions to inform decisions before problems arise.

By integrating both types of control, organizations can make smarter, data-backed decisions that improve efficiency. Managers can rely on real-time feedback to optimize processes while leveraging feedforward systems to anticipate future needs and mitigate risks before they impact operations.

5. Increased Agility and Responsiveness

In today’s fast-changing business environment, agility is key. Feedback and feedforward control systems help businesses remain responsive to both internal and external changes. Feedback enables quick adjustments, while feedforward empowers companies to be proactive in their decision-making.

For example, in the retail industry, feedback control can be used to adjust inventory levels based on sales trends, while feedforward control can predict seasonal spikes in demand and ensure that stock levels are adjusted in advance. This combination of real-time responsiveness and proactive planning increases operational agility, helping businesses stay ahead of competitors.

Integrating Feedback and Feedforward Control

The true power of these control mechanisms comes when they are integrated. While feedback control addresses current issues, feedforward control anticipates future challenges, and together, they provide a comprehensive approach to operational efficiency. Businesses that integrate both types of control into their operations can continually improve their processes, mitigate risks, and maintain a competitive edge in the market.

youtube

Conclusion

Feedback and feedforward control systems are indispensable tools for enhancing operational efficiency. By providing a clear framework for reacting to current performance and anticipating future challenges, these control systems help businesses optimize processes, allocate resources wisely, and stay agile in a rapidly changing environment. Whether you are in manufacturing, service delivery, or any other industry, adopting feedback and feedforward control strategies can significantly improve your operations and drive long-term success.

SITES WE SUPPORT

Performance Feedback - Wix

SOCIAL LINKS Facebook Twitter LinkedIn

0 notes

Text

Advanced Tuning Techniques for High-Performance Servo Motor Systems

Servo motor systems have become critical components in modern manufacturing, automation, and robotics, where high precision and speed are essential. Tuning these systems to achieve peak performance is vital for maximizing productivity and minimizing errors. In this article, we’ll delve into advanced tuning techniques that enhance the performance of servo motor systems, ensuring they operate at their full potential.

Understanding Servo Motor Tuning

Servo motor tuning is the process of adjusting various parameters to optimize the motor’s response and accuracy. By fine-tuning aspects such as velocity, position, and acceleration, users can achieve a smoother and more controlled operation. Proper tuning leads to increased efficiency, reduced vibration, and extended motor lifespan.

Key Parameters in Servo Tuning

Before diving into advanced techniques, it’s important to understand the primary parameters in servo tuning:

Proportional Gain (P) — Controls the immediate response of the motor. A higher P-gain results in a quicker response, but it may lead to instability.

Integral Gain (I) — Adjusts the steady-state error over time. Higher I-gain corrects errors but can cause overshooting.

Derivative Gain (D) — Smoothens the motor’s response to changes, preventing sudden jerks and oscillations.

Advanced Tuning Techniques

Auto-Tuning for Baseline Adjustments

Auto-tuning software simplifies the initial tuning process, providing a baseline configuration by adjusting basic PID values. While auto-tuning doesn’t replace manual tuning, it can serve as a solid starting point, enabling engineers to refine settings further for more specific performance requirements.

Frequency Response Analysis

Frequency response analysis assesses the servo motor’s ability to handle various frequencies, providing insights into how well the system reacts to changes in input. By analyzing this data, engineers can fine-tune the servo to better handle higher frequencies, which is especially valuable in applications requiring rapid movements.

Notch Filtering for Vibration Reduction

Mechanical vibrations can degrade the performance and accuracy of a servo motor system. Notch filters help target specific frequencies responsible for these vibrations, minimizing their impact. This is especially beneficial in applications with high inertia or long armatures, where vibrations are more pronounced.

Feedforward Control for Enhanced Response

Feedforward control anticipates changes in system behavior, providing corrective action before errors occur. For high-performance applications, feedforward techniques — such as velocity and acceleration feedforward — help maintain precise control without waiting for PID feedback to kick in, leading to smoother and faster operations.

Adaptive Tuning for Real-Time Adjustments

Adaptive tuning automatically adjusts parameters in real time, ensuring optimal performance under changing conditions. This technique is valuable in applications where loads or operating conditions vary, as the system can dynamically adapt its parameters to maintain stability and responsiveness.

Using Sinusoidal Commutation for Enhanced Smoothness

Instead of traditional trapezoidal commutation, sinusoidal commutation provides a smoother current waveform, improving torque and reducing ripple. This advanced technique is particularly beneficial in applications requiring ultra-precise control and minimal vibration, such as CNC machines and robotic arms.

Torque Ripple Compensation

Torque ripple, the variation in torque during motor rotation, can affect the performance of a servo system. Torque ripple compensation uses algorithms to smooth out these variations, reducing oscillations and providing more stable operation. This technique is essential in applications requiring consistent torque, like those involving precision machining.

Implementing Resonance Suppression

Resonance in a servo motor system can lead to unwanted oscillations, especially in setups with long shafts or heavy loads. By using resonance suppression techniques, engineers can dampen these oscillations, ensuring that the servo motor remains stable and responsive even under challenging conditions.

Motor Co-Efficiency Calibration

Fine-tuning the motor’s co-efficiency factors helps balance efficiency and performance. Adjustments in these factors enable the motor to deliver the required torque and speed without overheating, which is crucial in high-load or continuous-operation scenarios.

Parameter Monitoring and Iterative Optimization

Advanced servo motor tuning doesn’t end after setup. Continuous parameter monitoring allows engineers to identify areas for improvement. Through iterative optimization, small adjustments can be made over time, enhancing performance based on real-world operating data.

Benefits of Advanced Tuning in Servo Motor Systems

Adopting these advanced tuning techniques offers several key benefits:

Increased Efficiency: Optimized tuning minimizes energy consumption, reducing operating costs.

Enhanced Precision: Fine adjustments in parameters lead to more accurate positioning, essential in fields like medical devices and aerospace.

Extended Lifespan: By reducing strain on components, tuning extends the operational life of servo motor systems.

Improved Stability: Techniques like resonance suppression and notch filtering prevent vibrations and oscillations, providing stable performance in all conditions.

Conclusion

Advanced tuning techniques provide servo motor systems with the precision and responsiveness required for today’s demanding applications. From frequency response analysis to feedforward control, these methods ensure that your servo motors operate with peak accuracy and efficiency. Whether you’re working in manufacturing, robotics, or automation, investing in these tuning practices can lead to significant performance gains.

0 notes

Text

FeedForward Automation

Feedforward control is an advanced automation strategy that aims to preemptively counteract disturbances before they affect a system’s output. Here are the key aspects of feedforward automation: Operating Principle Feedforward control uses sensors to detect potential disturbances and applies corrective action before the system is affected[1]. It requires an accurate mathematical model of the…

0 notes

Text

What is Feedback and Feedforward control in Automotive?

Feedback control – The system output to adjust the system input by correcting errors and disturbances. For example: Cruise control system to maintain a constant speed by measuring the actual speed and comparing it with the desired speed. Feedforward control – The system input to predict the system output and feedback control systems is used to correct the prediction errors and ensure…

View On WordPress

0 notes

Text

PID Controllers in the Age of AI Unleashing the Power of PID Control with Artificial Intelligence

PID controllers have long been the cornerstone of engineering control, effectively regulating a vast array of systems, from simple motors to intricate industrial processes. Their widespread adoption is a testament to their remarkable effectiveness and versatility. However, as technology advances and systems become increasingly complex, even PID controllers face certain challenges. This is where artificial intelligence (AI) steps in, offering a transformative approach to enhance PID control and unlock new possibilities.

PID Control: A Foundation for Engineering Excellence

PID controllers, operate by continuously monitoring the difference between the desired and actual output of a system. They then employ three control parameters – proportional, integral, and derivative – to adjust the system's input accordingly. This feedback loop ensures that the output closely matches the desired value, maintaining system stability and achieving optimal performance. PID controllers have found widespread application in a vast array of engineering systems, including:

Industrial process control: PID controllers are commonly used to regulate temperature, pressure, flow, and other critical parameters in industrial processes, ensuring consistent product quality and maximizing efficiency.

Robotics: PID controllers play a crucial role in robotics, controlling the movement of motors, actuators, and servo mechanisms with precision and accuracy, enabling robots to perform complex tasks and interact with their environment.

Automotive systems: PID controllers are employed in various automotive systems, such as engine control, transmission control, and suspension control, optimizing performance, fuel efficiency, and safety.

AI's Role in PID Control Enhancement

AI, with its ability to learn from data and adapt to changing conditions, presents a unique opportunity to augment PID control, overcoming its inherent limitations and propelling it to new heights of efficiency and precision. A diverse range of AI algorithms can be employed to enhance PID control, each offering unique advantages and capabilities.

Reinforcement learning algorithms, for instance, can learn optimal PID parameters through trial-and-error interactions with the system, continuously improving performance.

Neural networks, on the other hand, excel at pattern recognition and can extract complex relationships from system data, enabling them to predict disturbances and proactively adjust PID parameters.

Fuzzy logic algorithms, inspired by human reasoning, can handle imprecise and uncertain information, making them suitable for controlling systems with non-linear dynamics or incomplete data.

Additionally, genetic algorithms can optimize PID parameters by mimicking natural selection processes, effectively navigating complex parameter spaces. The choice of AI algorithm depends on the specific characteristics of the system being controlled and the desired performance objectives.

AI algorithms enhance PID controllers, including:

Real-Time Adaptation: Traditional PID controllers struggle to adapt to dynamically changing environments. AI algorithms, however, can continuously analyze sensor data and adjust PID parameters in real-time, ensuring optimal performance even under unpredictable conditions.

Complex System Optimization: With the increasing complexity of modern systems, manual tuning of PID parameters can become a daunting task. AI algorithms can tackle this challenge by analyzing system behavior and automatically identifying the optimal PID parameters, maximizing system efficiency and stability.

Predictive Disturbance Compensation: Disturbances, both internal and external, can significantly impact system performance. AI algorithms can predict the effects of these disturbances and provide feedforward control, proactively adjusting the PID controller's response to minimize their impact.

By combining PID control's inherent strengths with AI's adaptability and learning capabilities, we can create a powerful control paradigm that surpasses the limitations of either technique alone. AI algorithms can complement PID control by providing real-time adaptation, optimizing parameters for complex systems, and mitigating the impact of disturbances. This synergistic approach opens up a world of possibilities for improving system performance, efficiency, and reliability.

AI-Enhanced PID Control: A Revolution in Engineering

The integration of AI into PID control has the potential to revolutionize a wide range of industries and applications. In industrial process control, AI-enhanced PID controllers can optimize production processes, reduce energy consumption, and improve product quality. In robotics, AI can enhance the precision and responsiveness of robots, enabling them to perform complex tasks with greater accuracy and efficiency. In automotive systems, AI-enhanced PID control can improve fuel efficiency, reduce emissions, and enhance vehicle performance and safety.

Conclusion

PID controllers have been instrumental in shaping the modern engineering landscape, but their capabilities are now being further amplified by the transformative power of AI. By combining these two powerful techniques, we can unlock new levels of performance, efficiency, and adaptability in a wide range of systems, paving the way for a future where engineering control reaches even greater heights. As AI continues to evolve, we can anticipate even more innovative applications of AI-enhanced PID control, shaping the future of engineering and driving technological progress.

Elevate your Control Systems with Theta Controls in Pune! Explore our Industrial Control System solutions, Process Control Instruments, Controller Control System, Programmable Temperature Controllers, Process Indicators, Paperless Recorders, and more. Upgrade your systems today for unparalleled efficiency and accuracy. Contact Theta Controls now!

#Programmable Temperature Controller in Pune#Thyristor Power Controller in Pune#Process Control Instruments in Pune#Process Indicator Controller in Pune#Temperature Control Systems And Accessories In Pune#Paperless Chart Recorder manufacturer in India

0 notes

Text

High Speed Linear Motors Are Ready For Delivery To UK

High Speed Linear Motors from Tallman Robotics Will be Transported To UK.

Can you provide examples of control algorithms commonly used for High Speed Linear Motors? Certainly! Here are a few examples of control algorithms commonly used for linear motors: 1. Proportional-Integral-Derivative (PID) Control: PID control is a widely used control algorithm for High Speed Linear Motors. It calculates the control signal based on the error between the desired position and the actual position feedback. The PID controller consists of three components: the proportional term, the integral term, and the derivative term. The proportional term provides immediate response to the position error, the integral term eliminates steady-state errors, and the derivative term improves stability and responsiveness by anticipating future error trends. 2. Model Predictive Control (MPC): MPC is an advanced control algorithm that uses a mathematical model of the system to predict its future behavior. It optimizes a cost function based on the predicted trajectory and control inputs to generate the control signal. MPC takes into account system dynamics, constraints, and future setpoints to achieve precise motion control. It is particularly effective in applications where there are constraints on the motor and system behavior, such as minimizing overshoot or avoiding collisions. 3. Sliding Mode Control (SMC): SMC is a robust control algorithm that aims to make the system track the desired trajectory regardless of uncertainties and disturbances. It creates a sliding surface that the system attempts to reach and maintain. SMC uses a switching control law that actively adjusts the control signal based on the position error and its rate of change. This algorithm is known for its ability to handle nonlinearities and external disturbances, making it suitable for applications with varying loads or changing environmental conditions. 4. Adaptive Control: Adaptive control algorithms continuously adjust the control parameters based on thesystem's characteristics and changes in the operating conditions. These algorithms use online estimation or identification techniques to adapt to varying system parameters, such as load variations or changes in friction. Adaptive control algorithms aim to maintain accurate motion control by continuously updating the control signal based on the estimated or identified system parameters. 5. Feedforward Control: Feedforward control algorithms compensate for known disturbances or feedforward signals to achieve precise motion control. These algorithms calculate and apply a control signal based on the expected disturbance or desired trajectory before the feedback is received. Feedforward control algorithms can improve the system's response time and reduce tracking errors by preemptively compensating for known disturbances or inputs. It's important to note that the selection of the control algorithm depends on the specific requirements of the application, the system dynamics, and the desired performance criteria. Often, a combination of these control algorithms may be used to achieve the best results. The implementation details and parameter tuning of these algorithms may also vary depending on the specific control system and High Speed Linear Motors setup. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#ElectricLinearActuators#Highspeedactuators#HighSpeedLinearModule#HighSpeedMotorizedLinearActuators#IronlessMotors#Linearmodules#LinearMotionActuators#LinearMotors#Sensorsforlinearmotors

0 notes

Text

control activity

1.Control Mechanisms and Gaining a Competitive Advantage:

Control mechanisms are integral to a cafe's success and competitive edge. In a cafe, various control mechanisms can be employed to achieve this, including:

Financial Control: The oversight of financial aspects to ensure the cafe's sustainability and profitability.

Quality Control: Maintaining consistent high-quality food and beverage standards for customer satisfaction and reputation.

Inventory Control: Efficient management of ingredient and supply inventory to reduce waste and costs.

Operational Control: Supervision of daily activities, like staff scheduling and workflow, for optimal efficiency.

Marketing and Promotion Control: Evaluating the effectiveness of marketing initiatives to attract and retain customers.

Feedback and Customer Satisfaction Control: Gathering and analyzing customer feedback to make enhancements and uphold a positive reputation.

2.The Importance of Control:

Control is indispensable for several reasons in a cafe:

Efficiency: It ensures the efficient use of resources, including time, labor, and ingredients.

Consistency: Control mechanisms maintain uniform product quality and service standards, crucial for customer satisfaction.

Cost Management: Effective control minimizes costs, leading to improved profitability.

Risk Management: It helps identify and mitigate risks before they become major issues.

Competitive Advantage: Proper control can distinguish a cafe from its competitors and enhance its reputation.

3.Types of Controls:

A cafe can implement various types of control:

Preventive Control: Measures to prevent issues, such as staff training to reduce errors in food preparation.

Concurrent Control: Real-time monitoring of ongoing operations, like tracking sales and inventory in real-time.

Feedback Control: Adjustments based on past performance data, such as modifying the menu based on customer preferences.

Feedforward Control: Anticipatory measures taken in preparation for future challenges, like gearing up for seasonal fluctuations in demand.

4.Control Systems in Operations:

Control systems are vital in the daily operations of a cafe. For instance, a cafe can employ a Point of Sale (POS) system as a control mechanism to monitor sales, manage inventory, and provide real-time data for decision-making. Inventory management software can also be utilized to control stock levels and minimize waste.

Organizational Control and Steps in the Control Process:

In an organizational context, control in a cafe involves a series of steps:

Setting Standards: Defining performance standards and objectives for various aspects of the cafe, such as quality, cost, and service.

Measuring Performance: Gathering data on cafe operations to evaluate performance against the established standards.

Comparing Performance and Standards: Analyzing the data to identify deviations from standards, whether positive or negative.

Taking Corrective Actions: Implementing changes and improvements to address any deviations and enhance cafe operations.

1 note

·

View note

Text

Interesting Papers for Week 13, 2024

The self and the Bayesian brain: Testing probabilistic models of body ownership through a self-localization task. Bertoni, T., Mastria, G., Akulenko, N., Perrin, H., Zbinden, B., Bassolino, M., & Serino, A. (2023). Cortex, 167, 247–272.

A whole-task brain model of associative recognition that accounts for human behavior and neuroimaging data. Borst, J. P., Aubin, S., & Stewart, T. C. (2023). PLOS Computational Biology, 19(9), e1011427.

Inhibitory tagging in the superior colliculus during visual search. Conroy, C., Nanjappa, R., & McPeek, R. M. (2023). Journal of Neurophysiology, 130(4), 824–837.

Hippocampal representation during collective spatial behaviour in bats. Forli, A., & Yartsev, M. M. (2023). Nature, 621(7980), 796–803.

Emergence of belief-like representations through reinforcement learning. Hennig, J. A., Romero Pinto, S. A., Yamaguchi, T., Linderman, S. W., Uchida, N., & Gershman, S. J. (2023). PLOS Computational Biology, 19(9), e1011067.

Error-independent effect of sensory uncertainty on motor learning when both feedforward and feedback control processes are engaged. Hewitson, C. L., Kaplan, D. M., & Crossley, M. J. (2023). PLOS Computational Biology, 19(9), e1010526.

Multiple memory systems for efficient temporal order memory. Jafarpour, A., Lin, J. J., Knight, R. T., & Buffalo, E. A. (2023). Hippocampus, 33(10), 1154–1157.

How awareness of each other’s mental load affects dialogue. Knutsen, D., & Brunellière, A. (2023). Journal of Experimental Psychology: Learning, Memory, and Cognition, 49(10), 1662–1682.

Developmental trajectory of time perception from childhood to adolescence. Li, Y., Gu, J., Zhao, K., & Fu, X. (2023). Current Psychology, 42(28), 24112–24122.

A multi-layer mean-field model of the cerebellum embedding microstructure and population-specific dynamics. Lorenzi, R. M., Geminiani, A., Zerlaut, Y., De Grazia, M., Destexhe, A., Gandini Wheeler-Kingshott, C. A. M., … D’Angelo, E. (2023). PLOS Computational Biology, 19(9), e1011434.

The inhibitory control of traveling waves in cortical networks. Palkar, G., Wu, J., & Ermentrout, B. (2023). PLOS Computational Biology, 19(9), e1010697.

Inferring local structure from pairwise correlations. Rahman, M., & Nemenman, I. (2023). Physical Review E, 108(3), 034410.

Beyond ℓ1 sparse coding in V1. Rentzeperis, I., Calatroni, L., Perrinet, L. U., & Prandi, D. (2023). PLOS Computational Biology, 19(9), e1011459.

Linguistic law-like compression strategies emerge to maximize coding efficiency in marmoset vocal communication. Risueno-Segovia, C., Dohmen, D., Gultekin, Y. B., Pomberger, T., & Hage, S. R. (2023). Proceedings of the Royal Society B: Biological Sciences, 290(2007).

Mnemonic discrimination deficits in multidimensional schizotypy. Sahakyan, L., Wahlheim, C. N., & Kwapil, T. R. (2023). Hippocampus, 33(10), 1139–1153.

An imbalance of excitation and inhibition in the multisensory cortex impairs the temporal acuity of audiovisual processing and perception. Schormans, A. L., & Allman, B. L. (2023). Cerebral Cortex, 33(18), 9937–9953.

Spike-timing dependent plasticity partially compensates for neural delays in a multi-layered network of motion-sensitive neurons. Sexton, C. M., Burkitt, A. N., & Hogendoorn, H. (2023). PLOS Computational Biology, 19(9), e1011457.

Development of human hippocampal subfield microstructure and relation to associative inference. Vinci-Booher, S., Schlichting, M. L., Preston, A. R., & Pestilli, F. (2023). Cerebral Cortex, 33(18), 10207–10220.

Task-dependent optimal representations for cerebellar learning. Xie, M., Muscinelli, S. P., Decker Harris, K., & Litwin-Kumar, A. (2023). eLife, 12, e82914.

Dissecting the chain of information processing and its interplay with neurochemicals and fluid intelligence across development. Zacharopoulos, G., Sella, F., Emir, U., & Cohen Kadosh, R. (2023). eLife, 12, e84086.

#neuroscience#science#research#brain science#scientific publications#cognitive science#neurobiology#cognition#psychophysics#neurons#neural computation#neural networks#computational neuroscience

20 notes

·

View notes

Text

Best selling of busbar punching cutting line

Busbar punching cutting line (busbar machine)is mainly used in high and low voltage switchgear, transformer manufacturing industry, for processing various specifications of copper and aluminum busbar. As long as the user is in the corresponding processing unit, the busbar can be punched, sheared. And bent separately, and the production efficiency is high. The bending unit of busbar shear adopts numerical control mode and has memory function at the same time(busbar bending machine).

The user can input processing data in advance, and the system can call out data for processing according to the input information. The field data of processed workpiece can be stored in the system at any time And can be called out for repeated use. The user can select the current coordinate value according to the thickness arrangement. And the required bending angle at any time before horizontal bending Or vertical bending processing. Busbar punching cutting line is a kind of high efficiency and high precision bus bar punch controlled by computer.

It is a bus bar production line with high automation, accurate positioning. Convenient use, high efficiency. And high performance, which combines automatic feeding, automatic positioning, automatic clamping, automatic punching. Automatic displacement, automatic cutting, and perfect combination Voltage switch cabinet, transformer manufacturing, box-type substation. Bus duct and other industries are used for automatic processing of copper and aluminum bus bars of various specifications. The machine has the advantages of high processing speed and high precision without manual intervention.

With busbar shear, it can generate busbar shear.

The numerical control technology is developing to a wider range of fields. Many busbar punches are developing towards intelligent, open, and network. The goal of CNC technology development is to improve the intelligence and digitization of CNC technology. In the field of mechanical production in China, the level of numerical control technology must be constantly improved, so as to meet the needs of social and economic development, and to adapt to the development trend of the times. The application of numerical control technology in the field of mechanical engineering is manifested in automobile manufacturing and aviation equipment manufacturing. The manufacturing of these machines belongs to the technology concentration type.

CNC technology can effectively control the production of these machines and ensure the accuracy and standardization of production. Because the manufacturing of these machines is closely related to people's life and safety, even the fault of a part may cause serious losses, so we must keep scientific and cautious in the manufacturing process. Manual operation is easy to cause problems in the manufacturing process due to physical reasons or errors, so there is no way to maintain the standardization and accuracy of the manufacturing process.

The application of this numerical control technology can avoid such problems and improve the precision of the manufacturing. Manufacturing precision and standardization is also the development trend of data technology. Intelligent, open, and networked are the main trends. In the 21st century, the CNC equipment will be a certain intelligent system.

The intelligent content includes all aspects of the CNC system.

In order to pursue intelligent processing efficiency and quality. For example, self-adaptive control of machining process and automatic generation of process parameters; intellectualization for improving driving performance and convenient connection, such as feedforward control, adaptive calculation of motor parameters, automatic identification of load, automatic selection model, self-tuning, etc. Intellectualization of simplified programming and simplified operation, such as intelligent automatic programming and intelligent human-computer interface, etc.

There are also intelligent diagnoses, intelligent monitoring content, convenient system diagnosis, and maintenance. Numerical control technology has become the core of advanced manufacturing technology, which is the basis of automation, networking, flexibility. And integration of the manufacturing industry. The practical high-speed machining technology has been widely used in the mechanical manufacturing industry along with the introduction of advanced CNC automatic production lines, cutting tools, and CNC machine tools.

The overall level of CNC equipment has gradually become the symbol of a country's industrial modernization level. And comprehensive national strength. Only by taking effective competitive strategies, implementing feasible competition plans, continuously improving the independent innovation ability, management level. And service quality of enterprises through an information system. And persistently cultivating long-term and sustainable development core competitiveness, can China's machinery manufacturing enterprises remain invincible in the international competition.

1 note

·

View note

Text

Watch "Feedback and Feedforward Control" on YouTube

youtube

Digital dashboard for control and voice command with voice over internet protocol management system AI drop in kits

0 notes